$40,000 Saved Per Year with Improved Settling at Dairy Plant

BioRemove FOG lowered the operating costs at a dairy plant by enabling treatment of a high-strength waste stream and improved settling.

Benefits

- Lowered operating cost by reducing chemical, disposal, and labor costs

- Improved plant efficiency through significant improvement in BOD removal

- Simplified operations by increasing treatment capacity to enable addition of a high-strength waste stream into the wastewater treatment process

Background

A filamentous bulking can be caused by many things in a dairy plant. Problems associated with bulking include minimization or loss of settleability and murky foam-like substances on aeration tanks. When such problems get out of control, permits can be violated and operating costs can increase.

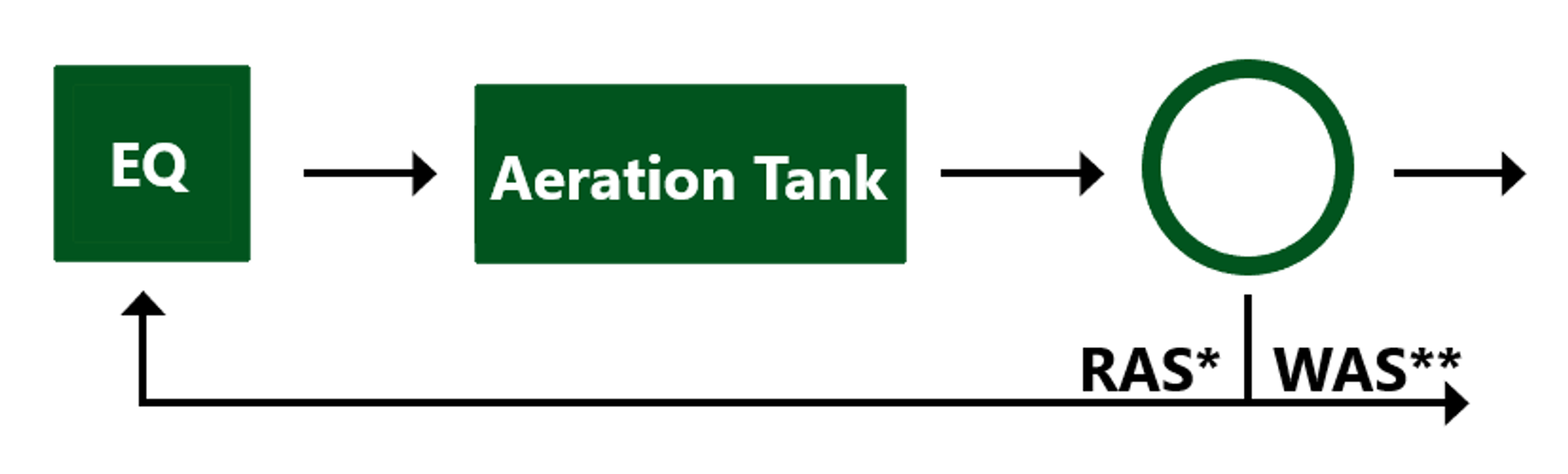

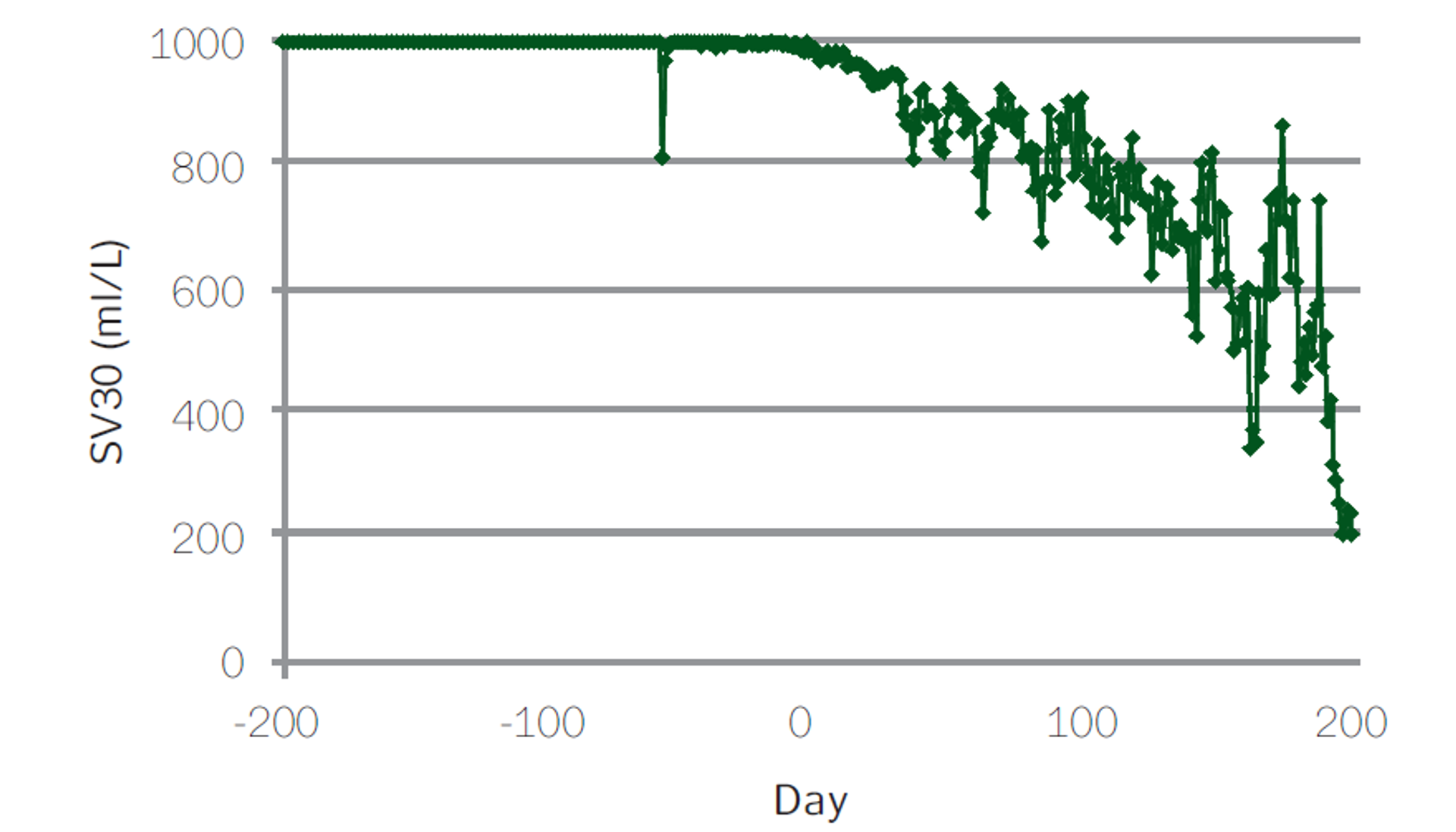

At a dairy production plant, changes in production led to increased FOG levels and severe settling issues shown by an unusually high value of SV30 (over 980 ml/L for over nine months). In order to meet the suspended solids permit, the heavy use of chemical coagulants in the clarifier was required. The dairy plant had unsuccessfully tried chlorination and later tried neutralizing the influent pH, which resulted in only minimal success. In order to meet the permit, the clarifier required constant attention from operators. A solution to simplify operations and increase treatment capacity was sought.

| Flow | 1.9 MGD (7192m3/day |

|---|---|

| Influent BOD | 500 mg'L |

Application

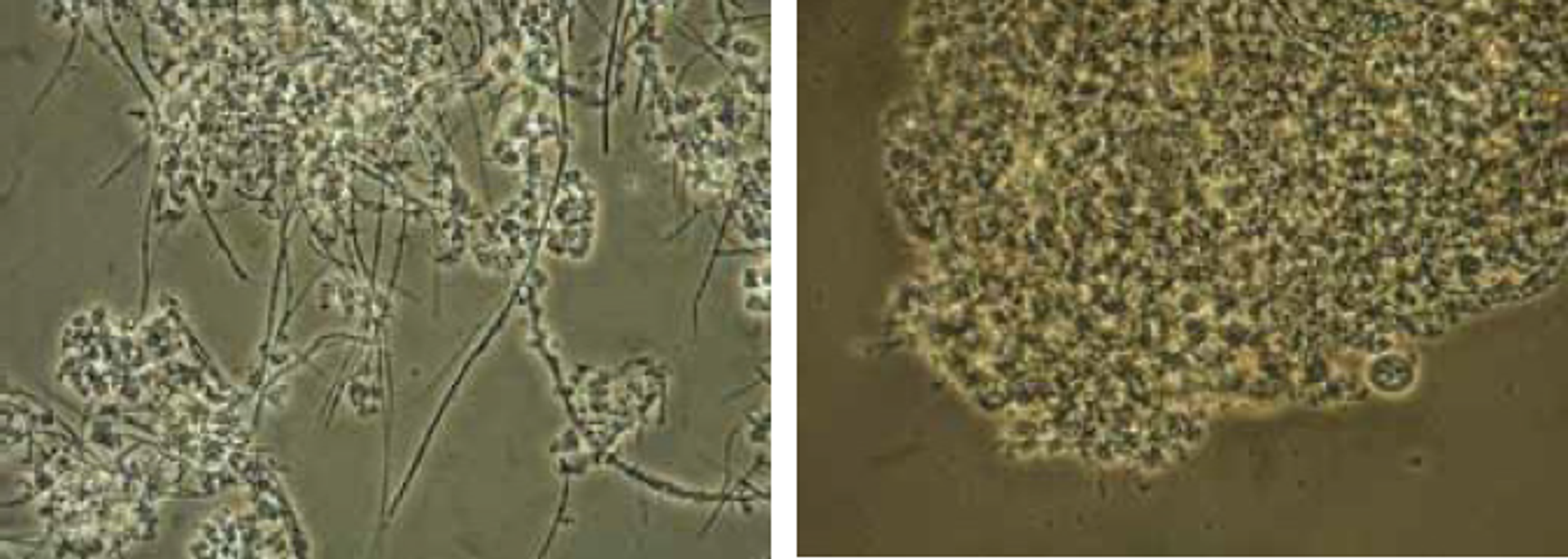

After assessment of the situation, the filamentous bulking problem was identified as the cause of these settling problems. A bioaugmentation program was proposed using BioRemove FOG.

Since fungi responsible for bulking are associated with pH below 6.5, the first part of the plan involved changing the pH of the equalization basin to 7.0. Also, nitrogen and phosphorous were added to the influent to satisfy a BOD:N:P ratio of 100:5:1 needed to have adequate activity of the biomass. A bioaugmentation program was recommended using BioRemove FOG to enhance BOD removal.

Results

Clarifier settling improved immediately and continued to improve over the next few months of the bioaugmentation program. As a result, chemical coagulants usage dropped to near nothing and less manpower was needed to operate the clarifier.

Observations through microscopic analyses revealed a reduction in filament abundance and an improvement in floc size and density. After four months of the program, a significant improvement in BOD removal efficiency was observed. This allowed the plant to begin treatment of a concentrated waste liquor (10% BOD) that had previously been too strong to treat. This material was being disposed of at a cost of $110 per day.

Conclusion

By supplementing the biomass with organisms that can effectively degrade FOG, the plant was able to divert a high-strength waste stream that was expensive to dispose of through the wastewater system and ease operations by solving settling issues. Use of BioRemove FOG resulted in:

- Lower operating costs

- Improved plant efficiency

- Simplified operations