Enhancing BOD Removal in Winter and Controlling Odor in Summer

The application of EnviroZyme’s OdorCap 5700 to the wastewater treatment system of a paperboard mill enhanced odor control during summer months, while BioRemove COD LT improved cold weather BOD removal in the fall and winter.

Benefits

- Lowered effluent BOD by 60% within one month during lower temperatures

- Significantly decreased odors during higher temperatures

Background — Winter

A container board manufacturer generates 1 million gallons (MG) of wastewater per day. It was treated with 2 extended aeration lagoons (14 MG each) and 1 polishing lagoon (3 MG). The treated wastewater was then discharged to the local Publicly Owned Treatment Works (POTW).

Every winter, this facility had experienced problems with elevated levels of BOD and TSS in the effluent. The plant was unable to handle fluctuating influent levels, which began to impact the POTW.

Application — Winter

The site was visited and technically assessed to begin troubleshooting the wastewater operation. This involved monitoring DO levels in various parts of the basin, checking oxygen uptake rates, measuring residual macronutrients, performing microscopic analyses, and reviewing all gathered data. It was decided that low water temperature (<10°C) was most likely the cause of suppressed biological activity.

A bioaugmentation program was proposed using BioRemove COD LT, a blend of bacterial strains specially selected for their ability to grow quickly in cold temperatures. The mill accepted the proposal and a trial began in January.

Results — Winter

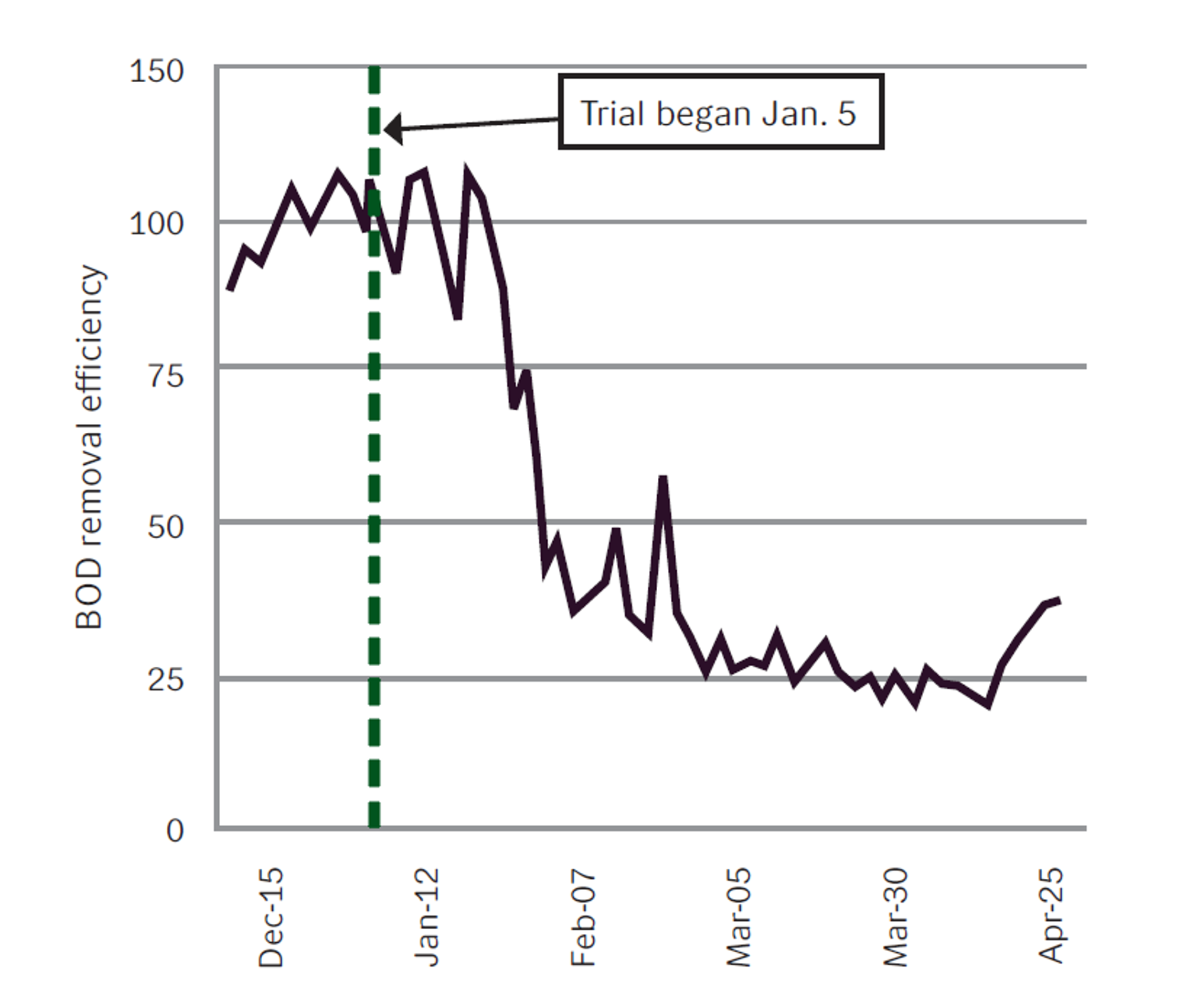

After a short inoculation period, BOD levels started to drop rapidly. In one month, effluent BOD was 60% lower than it was before the trial. Temperatures remained low through mid-March, and loading did not change significantly during the period.

Effluent BOD

Background — Summer

In the summer months, odor became a major concern at this mill. Warm temperatures allowed odor-causing compounds to easily strip into the air, permitting bacteria to grow faster in places where growth is not desired. When anaerobic conditions were present, hydrogen sulfide, reduced sulfur compounds, and organic acids caused a stink for miles around.

Application — Summer

To better understand where the odors were being generated, the mill underwent an in-depth analysis. Samples were taken from around the mill and specific odor-causing chemicals were identified. The analysis suggested the primary clarifier was the main culprit. A second bioaugmentation program, this time using EnviroZyme’s OdorCap 5700, was presented to mill management.

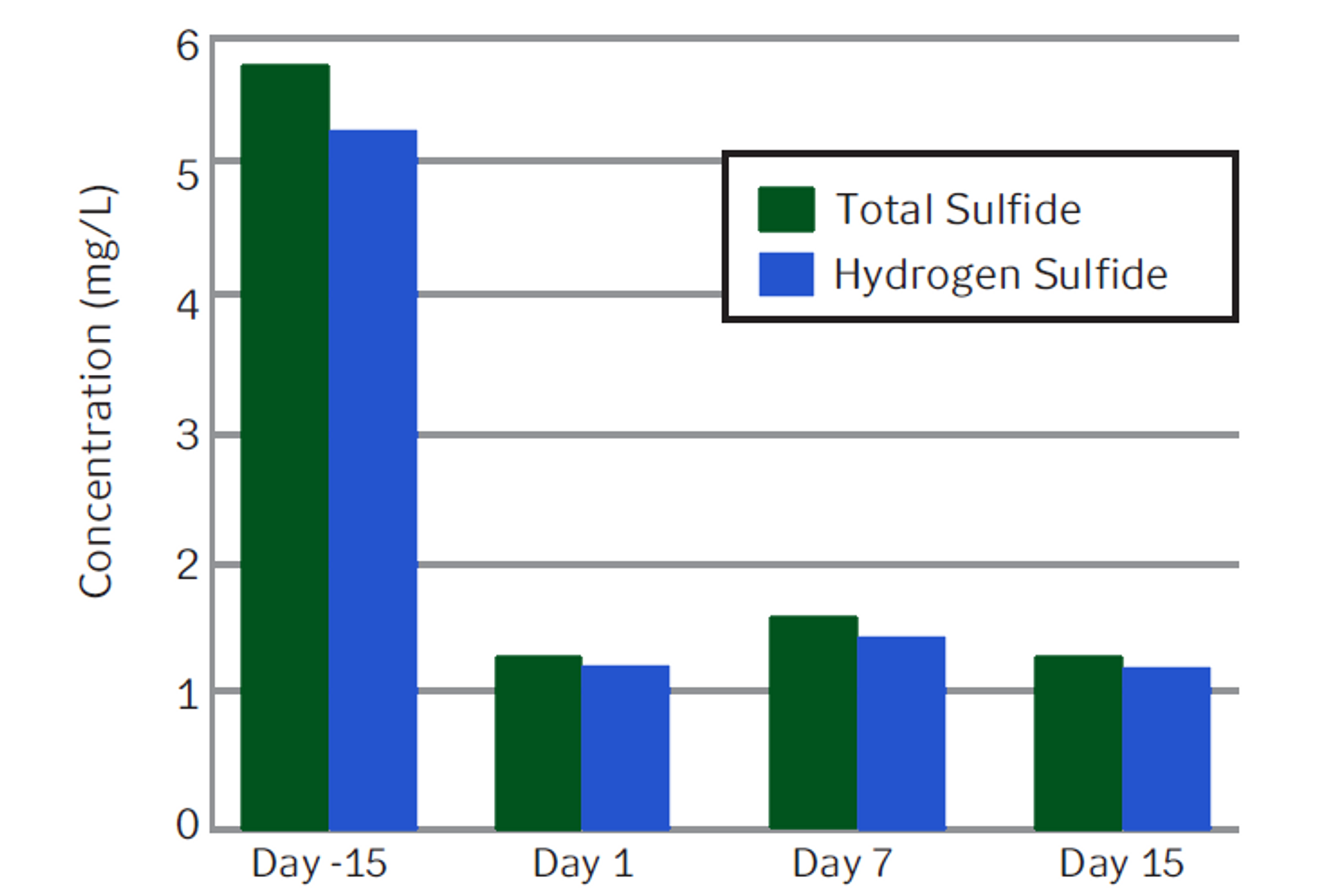

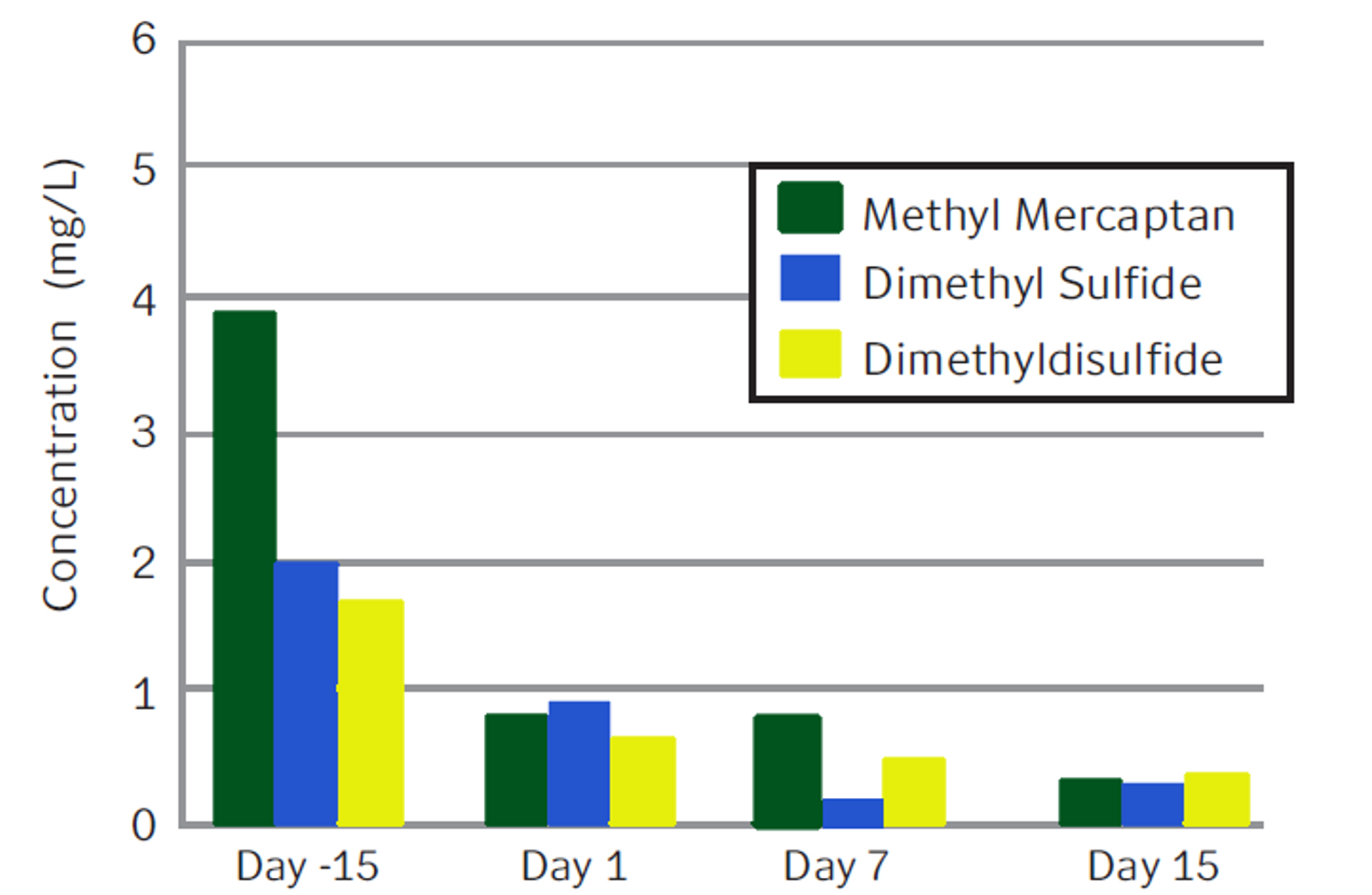

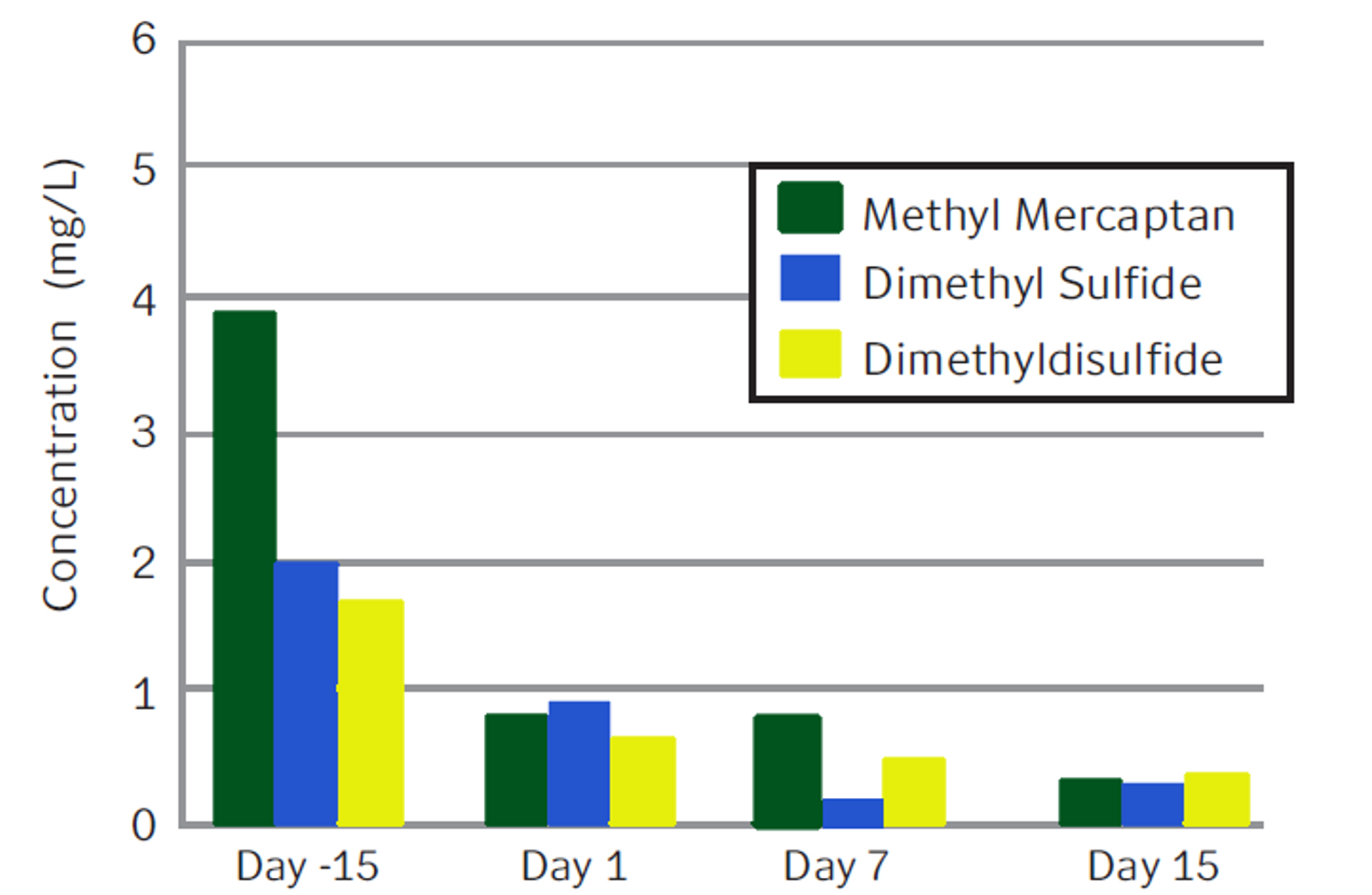

Results — Summer

During the first two weeks of the trial, concentration of the most relevant odor-causing compounds remained lower than pre-trial levels. The odor surrounding the primary clarifier was noticeably reduced.

Sulfides

Reduced Sulfur Compounds

Organic Acids

Conclusion

EnviroZyme’s bioaugmentation program was easy to implement and provided significant benefits: maintaining effluent quality during the winter, and controlling odors in the summer. EnviroZyme’s solutions resulted in:

- Lower operating costs

- Improved plant efficiency

- Simplified operations