Optimized Brewery Production by Decreasing COD Removal and Improving Water Quality

A treatment with BG Max 3000 was initiated in a brewery to optimize the performance of the wastewater treatment plant (WWTP).

Benefits

- Reduced the overall effluent COD by 23%

- Decreased recovery time from shock loads by more than 30%

Background

A brewery experienced wastewater treatment issues when transitioning from low level production to peak summer production periods. The plant sought to improve operations, and a bioaugmentation solution was investigated.

Application

After an on-site evaluation, it was recommended that BG Max 3000 be applied to the anaerobic digester to enhance reactor performance.

Results

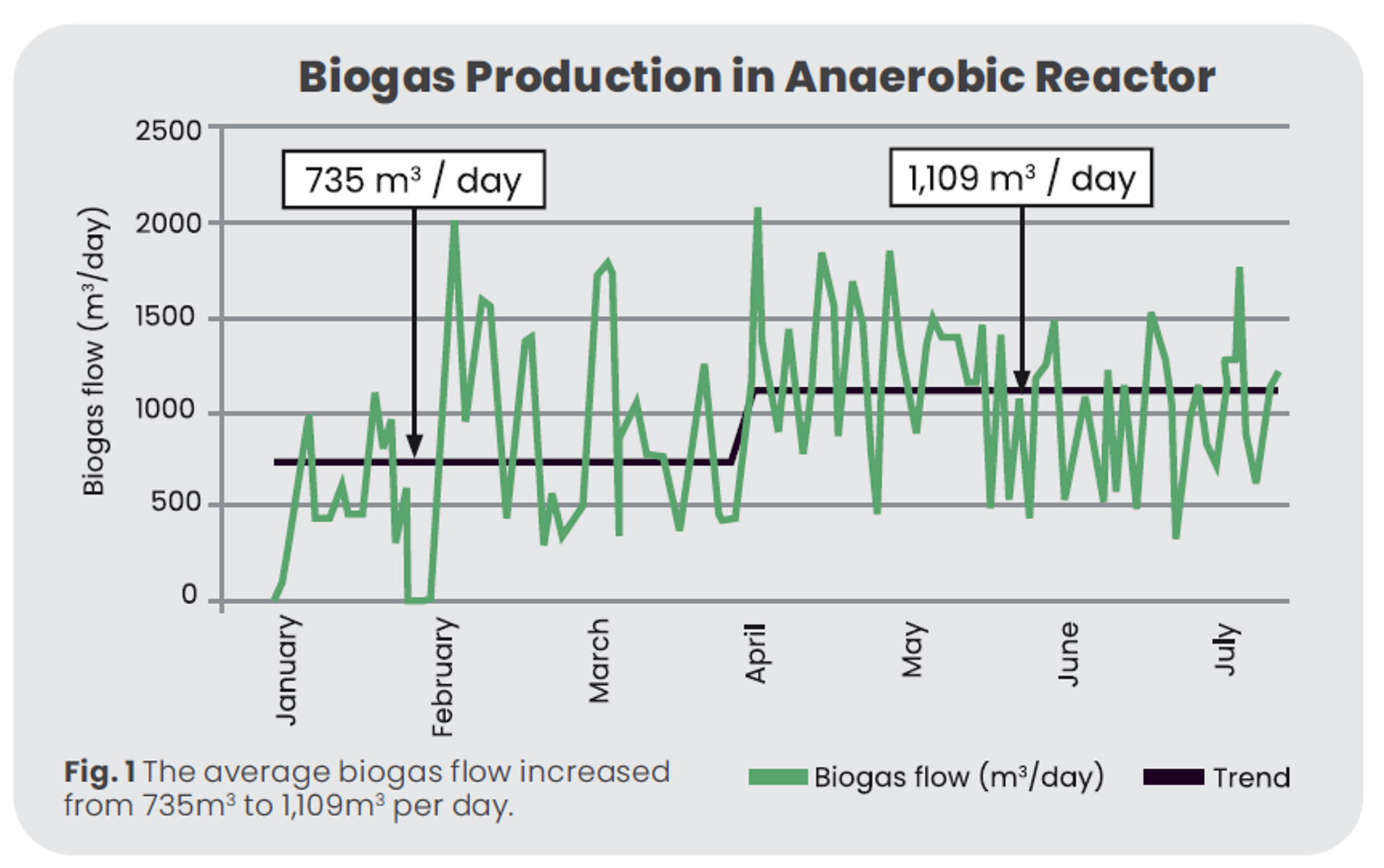

The amount of COD (kg/day) removed from the anaerobic reactor increased during the BG Max 3000 dosing period of the first week of April until the beginning of July. Higher biogas production was expected during this period with the higher inlet COD, but was limited due to the lack of alkalinity in the reactor.

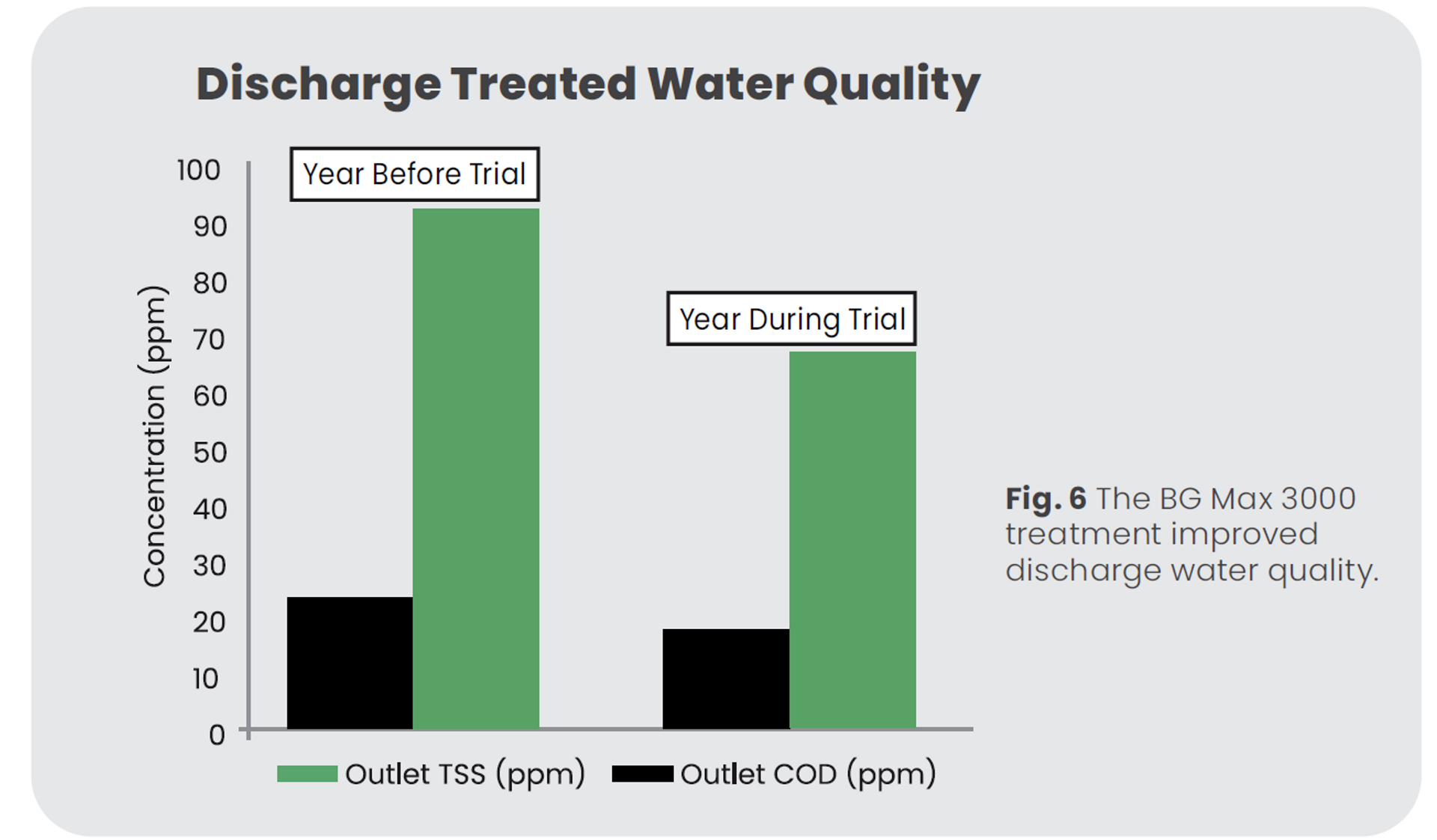

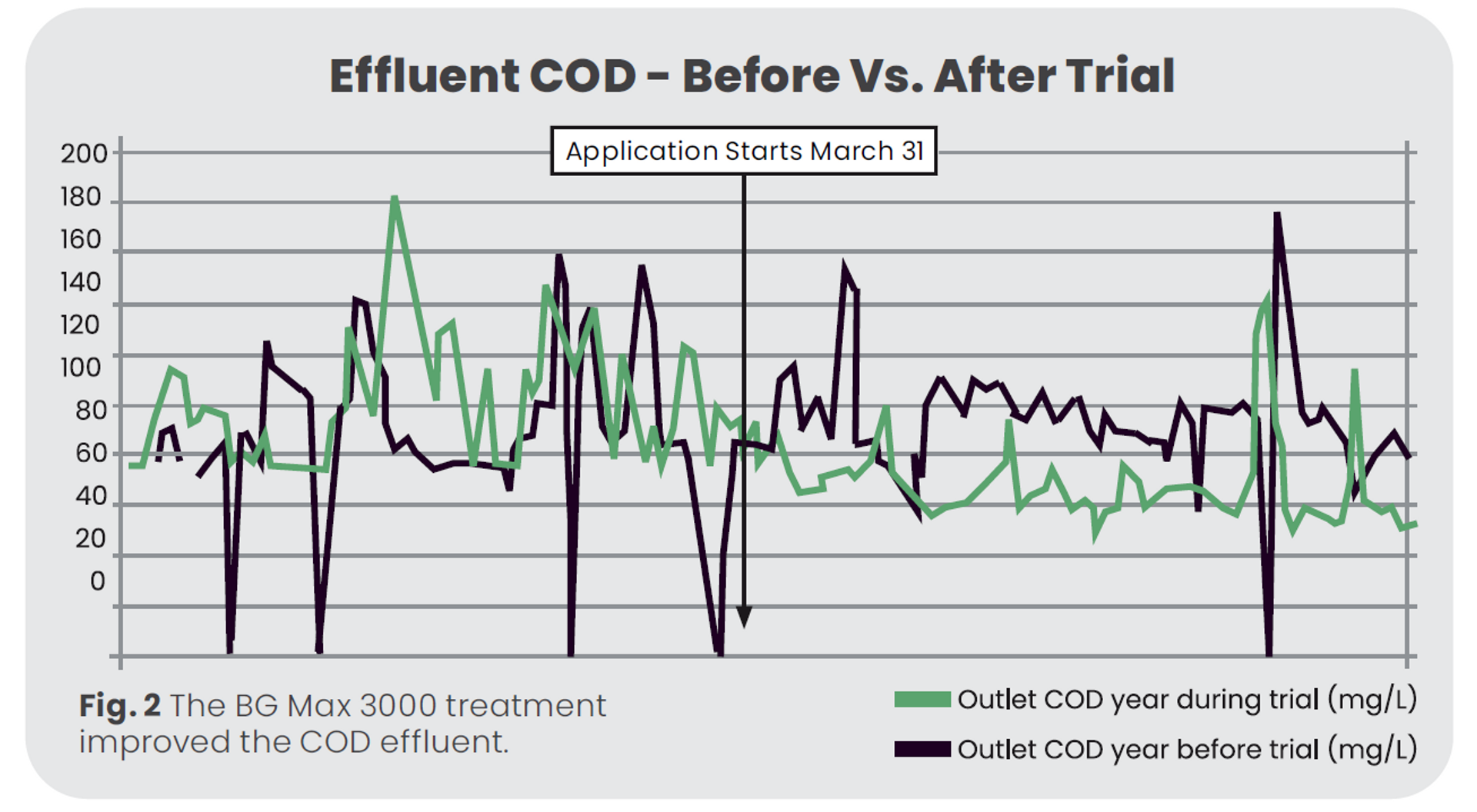

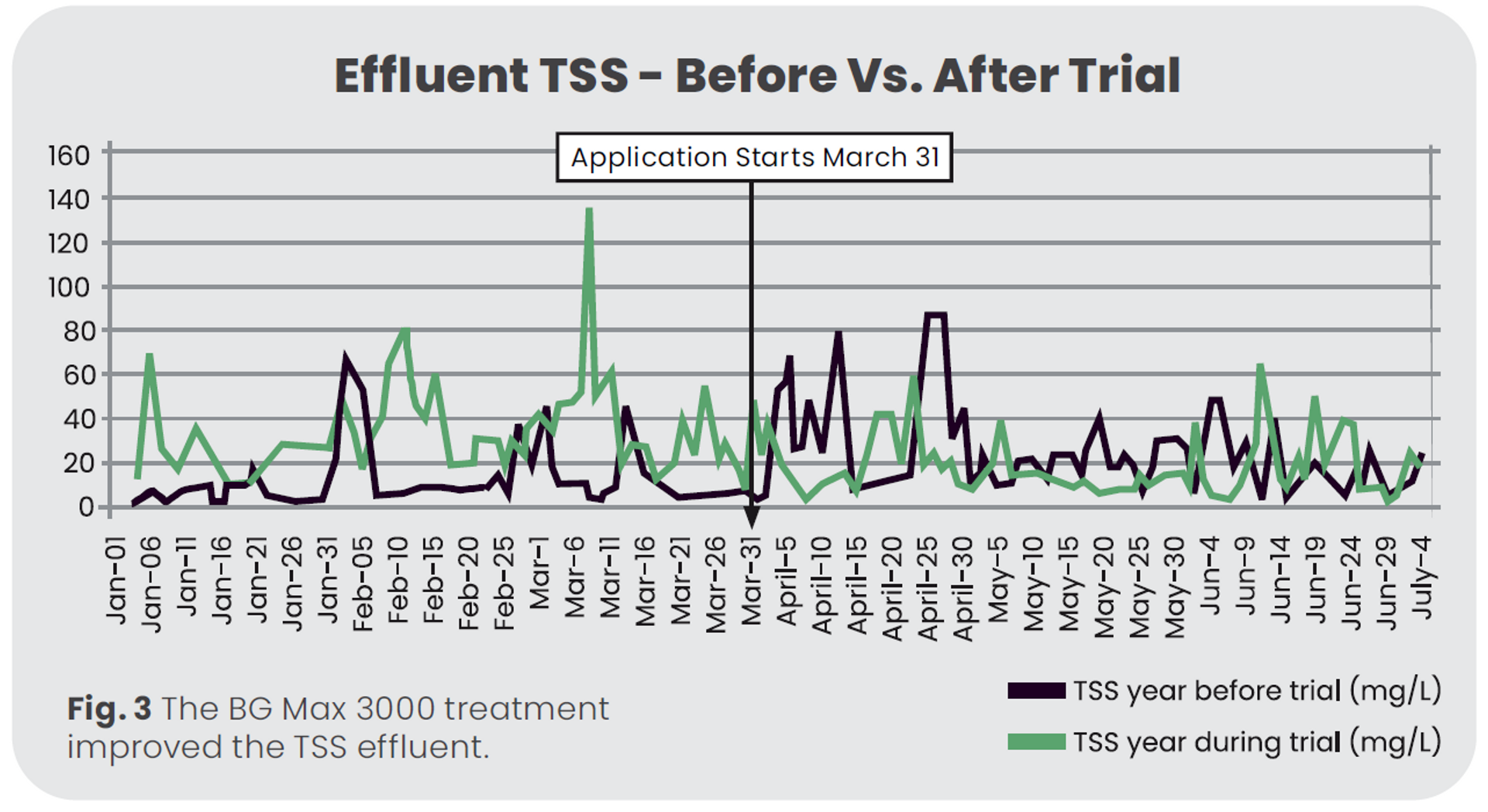

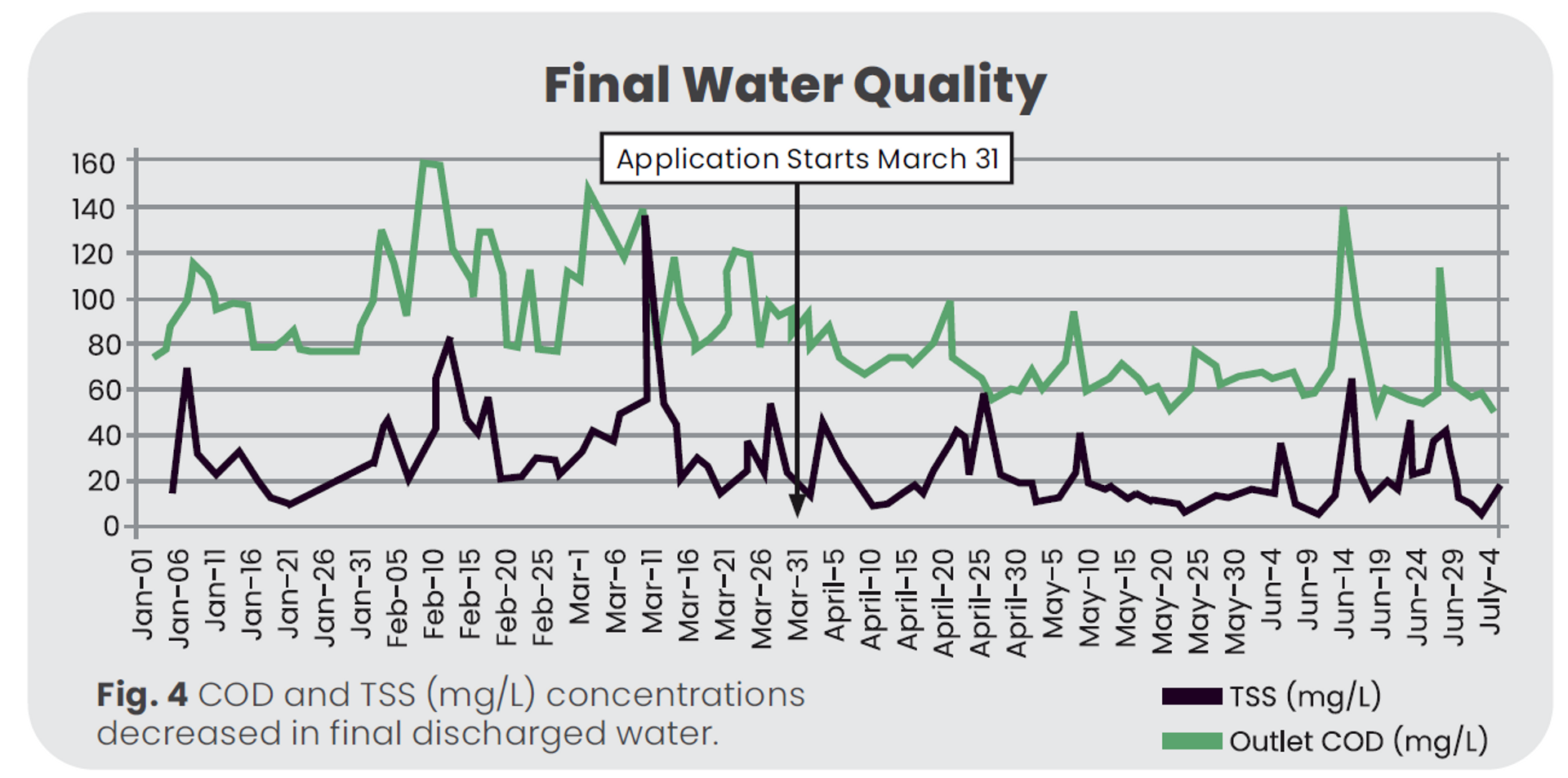

The secondary aerobic stage also benefited from BG Max 3000 treatment. The treatment improved the COD effluent, decreasing the month 5/6 average COD 39%, from 102 mg/L before the trial to 63 mg/L after the trial, even with the additional load in the influent.

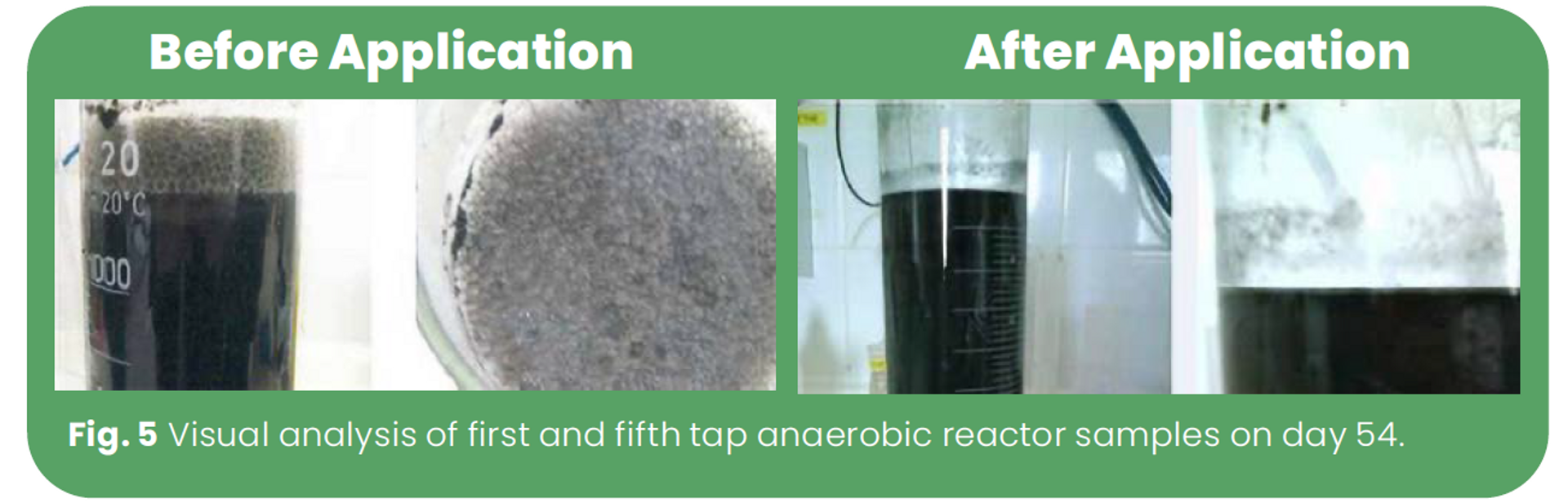

Before application of BG Max 3000, a slimy foam layer could be observed at the top of the anaerobic reactor. On day 36 of bioaugmentation treatment, visual analysis of samples were taken from the anaerobic reactor; the slimy foam layer was no longer observed.

Conclusion

By using BG Max 3000, the manufacturer was able to achieve their goals of improving water quality, increasing biogas production and increasing COD removal with the following associated benefits:

- Lower operating cost

- Simplified plant operations

- Improved plant efficiency